|

Nantong enerpat machinery co ltd

|

non ferrous metal baler

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

BUY GOOD QUALITY MACHINE FROM UK

TRUST UK TECH

IF YOU DO NOT WANT GET MORE PROBLEM FROM CHINA,CHOOSE UK EQUIPMENTS

TRUST THE PHOTOS

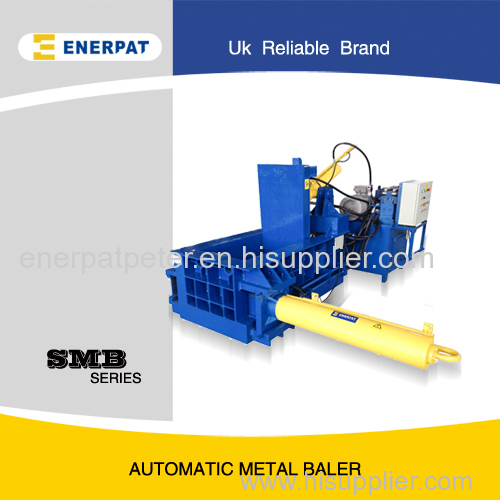

Specification Of The SMB-T160XL Scrap Metal Baler

| NO | Item | Unit | T160Xl |

| 1 | Press force | tons | 160 |

| 2 | Size of pressing chamber | mm | 1600*1200*800 |

| 3 | Size of bale | mm | 400*400 |

| 4 | weight of bale | kgs | 100-200 |

| 5 | Density of bale | Kg/m3 | 2000 |

| 6 | Cycle | s | 100 |

| 7 | Production Efficiency | ton/h | 2.0-4.0 |

| 8 | System pressure | Mpa | 25 |

| 9 | Motor power | kw | 37 |

| 10 | Size of machine | mm | 4100*4100*2600 |

| 11 | Weight of machine | tons | 15.0 |

This T160XL is a kind of Heavy Duty Metal Balers.It is a star in Enerpat Metal Baler Family in a decade.It is born with a 37 kw 415V 50Hz 3 phase SIEMENS motor,Nok Seal rings,Enerpat Rams and Packer Hose.

This Side Ejection Baler has a big pressing chamber,so it is perfect for loading more big size scrap metals.Like the steel shavings,scrap steels,scrap aluminium,scrap coppers,scrap stainless steels and so on,all these kinds of metal materials can be made into qualified furnace.And it is equipped with a hand valve control,which makes easy and safety operation for the operators.

We use the TOP brands such as the SIEMENS motor drive.And the machine press from three sides,which means the metals can be compacked into a high density bale.

Quality Features Of The SMB-T160XL Scrap Metal Baler

SIEMENS Motor Drive

Large Chamber

High Density Bales

Top Loading ,easy to operate

Original germany made SIEMENS motor;With cooler and hotter,for special temperature environment)

Big pressing chamber,1600mm for length,1200mm for width and 800mm for height.

Pressing From Three Side,which compact the scrap metals into one high density bales

Loading with grab bucket or Steel Conveyor;No installion demands, operating the baler directly;With control platform on the baler, convenient for operating